Elementary, an artificial intelligence machine vision company, closed on $30 million in Series B funding to continue developing its manufacturing quality and inspection tools.

We last profiled the Pasadena-based company last June when it raised $12.7 million in a financing round led by Threshold Ventures. Elementary’s tools enable customers to create no-code inspection routines and train models to inspect produced goods, parts and assemblies that were previously impossible to inspect manually, in a repeatable and scalable way.

With the latest funding, Threshold is back and participating with other existing investors, including Fika Ventures, Fathom Capital, Riot VC and Toyota Ventures, in a round led by Tiger Global. In total, the company has raised $47.5 million.

“Elementary’s rapidly deployable hardware and industrial machine vision software are powering modern factories,” said Mo Islam, Elementary board director and partner at Threshold Ventures, said via email. “I’m thrilled to welcome Tiger Global as a new partner for the company as they scale deployments with numerous customers in manufacturing, consumer packaged goods and logistics.”

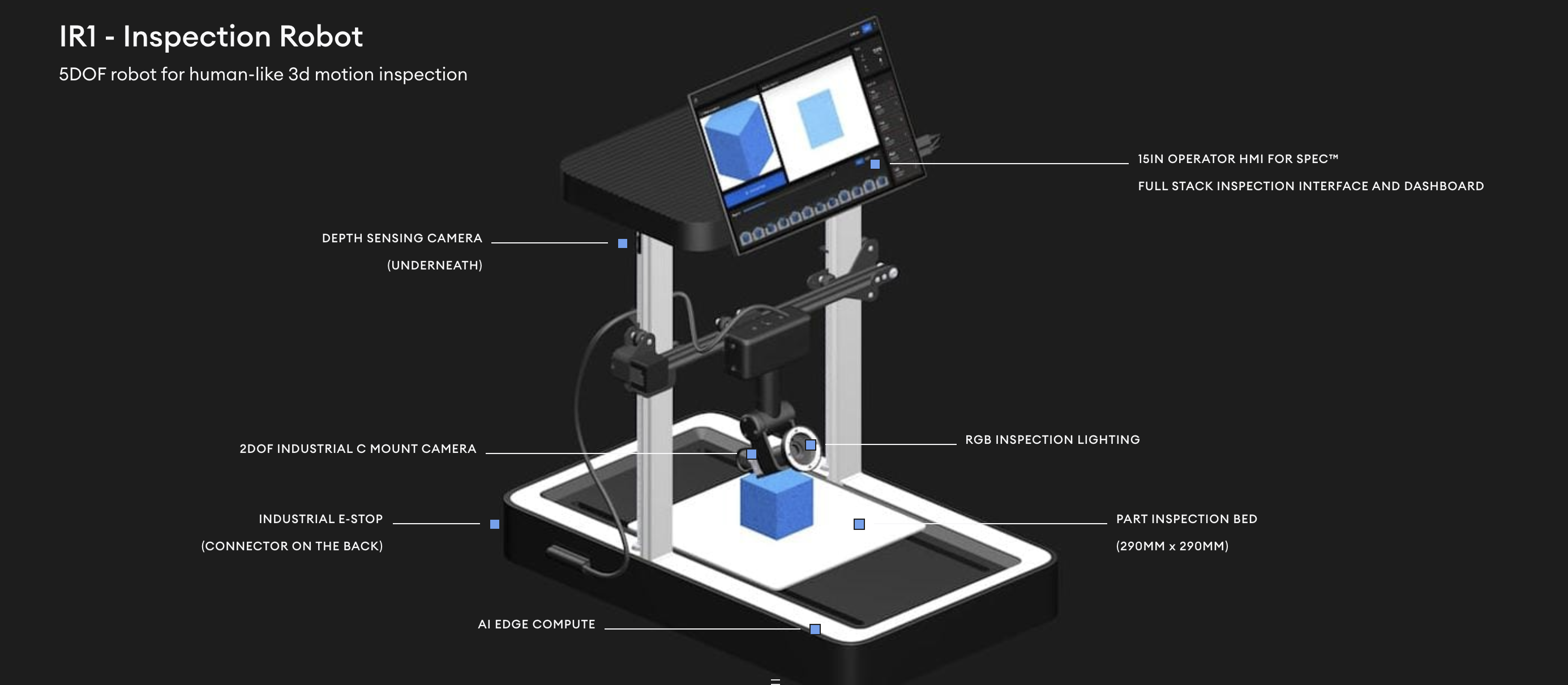

Elementary’s automated inspection tools. Image Credits: Elementary

Meanwhile, Arye Barnehama, founder and CEO of Elementary, explained via email that customer demand and market timing were the drivers for the company to go after new funding. Over 250 millions inspections have been performed to date, he said.

In the past year, the company grew its number of Tier 1 enterprise customers by 10 times. At the same time, Elementary’s team doubled its headcount and rounded out its executive suite with the hiring of Milind Karnik as vice president of engineering, Monique Apter, vice president of sales, Krishna Gopalakrishnan, senior director of vision and platform, and Greg McEntyre, vice president of implementation.

Barnehama intends the new funding to expand Elementary’s customer base globally. He also intends to double the company’s workforce over the next year by growing in engineering, sales, implementation and customer success teams. The company will also invest in technology development for additional AI inspection capabilities and cloud analytics and reporting.

“During the pandemic, manufacturing and logistics have undergone major labor shortages that were already beginning before the pandemic but were significantly increased,” Barnehama said. “As companies look to continue to automate without having to rely on expensive and hard to find engineering talent, our business has scaled because we are able to provide them with no-code AI solutions. Overall, we’re enabling customers to move towards industry 4.0 cloud initiatives, and quality/sustainability initiatives in a fast and easy path.”